CHOPPER PUMPS

Landia Chopper Pumps

The Unique Concept

Landia Chopper Pumps, with the unique external chopping system, are designed for pumping heavily contaminated liquids and sludge with high solids concentration.

The chopping system is completely separated from the pump casing and the impeller. This prevents blocking of the pump and its subsequent piping, as all chopping is completed before the liquid enters the pump housing. The wear on the pump casing, impeller and sealing system is significantly reduced due to the chopping system design.

Du to the open impeller design the Landia Chopper Pump is also ideal for pumping high viscosity liquids. If the pumped liquid is abrasive, the pumps are available with special hardened pump components which will extend the lifetime significantly compared to standard material.

Most Landia Chopper Pumps are also available in AISI 316 Stainless Steel for acidic liquids.

Landia Chopper Pumps can be found in wastewater application, in biogas plants, the food industry, mining and paper mills, to name a few. The applications are numerous and in general a Landia Chopper Pump takes over where other pumps give up.

Over 70+ Years of Chopper Pump Innovation

A Complete Pumping Product Line

Landia was founded in 1933 and is today a modern, successful manufacturer of a comprehensive range of chopper pumps, propeller mixers and aerators, offering customised solutions and systems for difficult to handle liquids with high dry matter content, liquid biomass and other organic waste.

Landia chopper pumps are available in many types and models in cast iron or stainless steel and can be tailor-made for your pumping system, including:

- Open impeller design

- Motors from 1.8-60 Hp (also available in explosion proof design)

- Single or extended knife systems

- Special hardened pump components for abrasive applications

- Pump casings and impellers in surface-coated cast iron or in stainless steel

- Adaption to existing installations

- Extensive line of equipment (e.g. combined pumping and mixing)

The Chopper Pump

Landia developed the first chopper pump in 1950. A chopper pump is a pump quipped with a knife system at the pump inlet. The knife system prevents the pump from clogging when the pumped liquid contains solids.

Originally, the Landia chopper pump was designed to chop the straw that was always present in liquid manure and often caused clossing of the pump.

The Landia pump design has proven so efficient, that the pump system has been refined even further into a pump that is ideal for municipal and industrial applications.

The applications are municipal & industrial wastewater, pumping of sludge, liquid biomass, by-products in the food industry, different kinds of abrasive liquids and any other type of challenging pump application.

Pumps Selection Tips:

Dry Mounted or Submersible?

In most cases the choice is obvious. However applications can be found where a shift from submersible to dry mounted pump is a good idea.

Material of Construction?

For the majority of applications the standard cast iron model is just perfect for the job. Landia pumps are available also in AISI 316 and hardened cast iron.

Characteristics of the liquid to be pumped?

This is essential and in most cases the liquid is very different from water. It can have a high solids content, high viscosity, containing rags or being abrasive. The pH will also influence the lifetime of the pump.

Liquid Temperature?

High Liquid Temperature, up to 80-90°C is normally not a problem for a dry mounted pump. A submersible pump has a max. liquid temperature of 50°C, since the pump motor relies on the surrounding liquid for cooling.

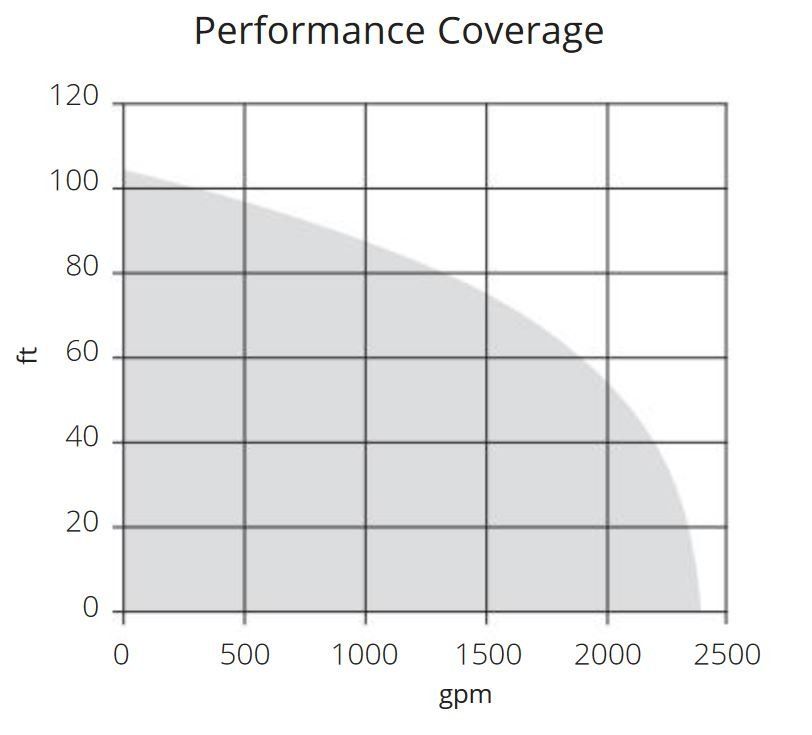

Pump Capacity?

The required capacity of the pump is usually determined by the flow and the head, derived from water-based pump curves. A Landia pump normally pumps higher viscocity liquids and so compensation must be applied.

A Complete Pump Range

Submersible Chopper Pump

In addition to the complete submersible pump installation with coupling flange in vertical installation, we are also able to supply pumps for horizontal installation or with an adapter for existing installations.

Chopper Pump for Dry Installation

Heavy duty pump with compact design that can be used for new and existing applications.

Available in horizontal & vertical installation

Gator Series

The EradiGator is a highly efficient chpper pump which is designed for pumping, mixing and chopping heavily contaminated wastewater.

All EradiGator pumps are equipped with a knife system at the inlet to the pump, which ensures non-clog operation under conditions in which many other pumps have to give up.

The EradiGator is typically used in lift stations where existing wastewater pumps face clogging problems due to wet wipes, oil, fats and grease. The EradiGator mixes by means of recirculation and breaks up the solids in the lift station to ensure hassle-free operation of existing lift station pumps.

Long Shaft Chopper Pump for Wet Well Installation

Extremely sturdy pump with liquid lubricated bearings.

Almost maintenance-free.

Especially suited for combined pumping and efficient mixing.

- Traditional sub-design

- Upgraded lower seal is standard

Heavy Duty Dredger Pump

Design features

- Maximises compacted material pumping capability

- High concentration of solids pumping up to 80%

- Higher excavating torque with reduced absorb power including operating costs

- Highly cost effective method of converting stationary material into a pumpable state to transfer compacted material such as gravel, clay, mud, sludge and slurry

- Versatile submersible drive mechanism (hydraulic or electric) eliminates lengthy cutter shafts, thus eliminating pump failure.

- Inbuilt agitator at bottom of pump creates high agitation and excavation motion, drawing the concentrated material continuously at high concentrations eliminating clogging strainer including pump

- Inbuilt strainer at bottom of pump provides a protective screen surrounding the pump intake, preventing ingress of oversized material which is ejected away by agitator, preventing pump clogging

- Heavy duty materials of construction ensures reliable pumping of high concentration of material with high chrome used in hey wear parts such as impeller, suction cover including agitator.

Specifications

- Solids handling up to 120mm dia.max

- Flows up to 795,000 L/hr

- Heads up to 50m

- Power up to 375kw

- Size up to 16"

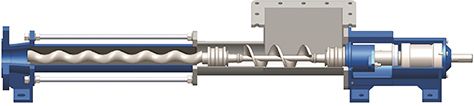

Progressive Cavity

Superior Quality Progressive Cavity Pumps

Manufactured To The Highest Industry Standards For Quality

The Millennium Series Progressive Cavity Pump

- Municipal

- Water

- Wastewater

- Sewage

- Industrial

- Construction

- Winery

- Mining

- Food processing

- Pulp and paper

Self Priming

Introducing the WAPSA Prime Hog Trash Pump

- Municipal

- Water

- Wastewater

- Sewage

- Industrial

- Construction

- Wine making

- Mining

- Food processing

- Pulp and paper processing

Submersible

Samurai Series

The Samurai Range

Read about the superior features of the Samurai Submersible Pumps by clicking on the links below

Cornell Pumps

A Long History of Innovative Solutions

Cornell's Industrial Product Line

Wide variety of sizes and configurations

Models range in size from 1" to 30" and a range of configuration options are available for each model - including frame and engine mount options and Cornell features like Run-Dry™ and Redi-Prime®.

Pumps designed for specific jobs

Cornell's team of expert engineers design pumps to meet the varying demands of industry applications, such as solids handling, slurry, and head requirements.

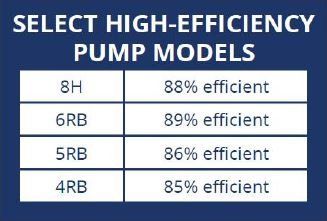

Outstanding Efficiencies

Cornell put their experience and knowledge to work to produce tested designs with some of the highest efficiencies of any pumps on the market.

Robust Construction

Cornell pumps are built using superior materials selected for their suitability to each pump’s intended application. Heavier casting walls, thicker shafts, and fully-machined impellers are part of what make Cornell pumps more rugged and durable than other pumps.

Quality Assurance

Cornell Pump proudly maintains its ISO 9001:2008 certification that validates Cornell is in compliance with all necessary processes to meet customer requirements.

The elements associated with ISO 9001:2008 certification include such areas as contract review, design and development, production, purchasing, quality control and service.

Cornell Features & Benefits

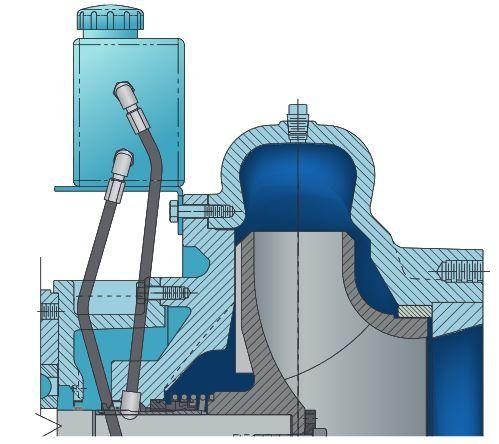

RUN-DRY™ SEAL PROTECTION

Cornell’s Run-Dry system consists of an auxiliary gland and oil reservoir that keeps the seal faces lubricated and prevents dry running of the seal faces during priming, re-priming, or standby operation.

- Run dry for hours without damaging the seal

- Cools and lubricates seal faces

- Ideal for applications that could experience dry operation

- Useable in conjunction with Cycloseal® and Redi-Prime®

CD4MCU STAINLESS STEEL OPTIONS

CD4MCu is a duplex stainless steel, with greater corrosive resistance than 304 stainless steel. CD4MCu allows the pumps to be used in more abrasive applications, and it won’t pit like 304 stainless steel, has a better stress/corrosive cracking resistance than 304 stainless, and higher strength than 304 stainless steel. And compared with cast iron material, it is much more resistant to corrosion and much stronger.

Cornell distributors have access to 11 of Cornell’s most popular models in CD4MCu, allowing us to slash production time and price. Cornell can supply a CD4MCu pump in as little as one to two weeks.

- Clean Steel

- Usable in pH levels of 2 to 13.5

- Brinell hardness up to 275

- Corrosion and pitting resistance

- Higher strength than 304 stainless steel

- Improved ductility and weldability

- Better resistance to embrittlement

REDI-PRIME® DRY-PRIMING OPTION

Cornell Redi-Prime pumps are designed with oversized suctions to provide more flow, reduced friction losses, and higher suction lift. The priming system was designed with the environment in mind. By using a positive sealing float box and a diaphragm vacuum pump, there is no water carry-over to contaminate the environment. Redi-Prime is offered on all Cornell industrial pumps, and is available in virtually every other pump we manufacture as well.

- Fully automatic priming and re-priming

- Handles air/liquid mixtures with ease

- Rapidly primes and re-primes completely unattended

- Environmentally safe priming system designed to prevent product leakage

- Handles large sized solids

- High suction lift capability up to 28 feet

- Premium hydraulic efficiency for reduced energy consumption

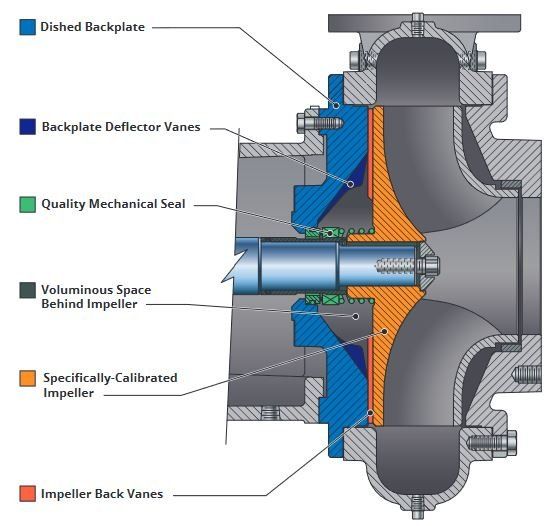

CYCLOSEAL® SYSTEM FOR GRIT REMOVAL

Cycloseal® is patented system with a self-contained single mechanical seal. The Cycloseal pattern cast into the pump backplate in conjunction with contoured impeller back vanes and a dished backplate, creates a pressure gradient that move solids and entrained vapor away from the seal faces. The Cycloseal system is available on most Cornell Pumps.

- Removes grit from pump seal compartment

- Extends pump seal life three times standard mechanical

- No drips/mess at application site

- Reduced maintenance costs

- Increased uptime and reliability

- Removes vapor

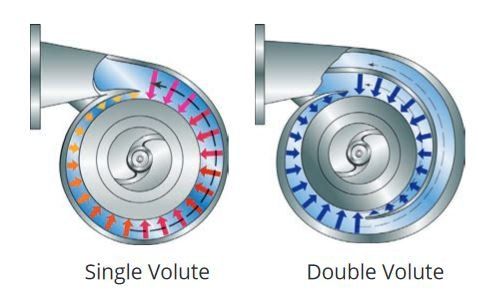

DOUBLE VOLUTE DESIGN

Cornell’s double volute system minimizes radial thrust loads common with high capacity, high-head centrifugal pumps, by balancing the radial forces around the impeller.

- Minimizes radial thrust load

- Eliminates shaft flexing and fatigue

- Greatly extends life of packing/seal, wear rings and bearings

- Effectively meets high pressure and high volume requirements

- Increases bearing life

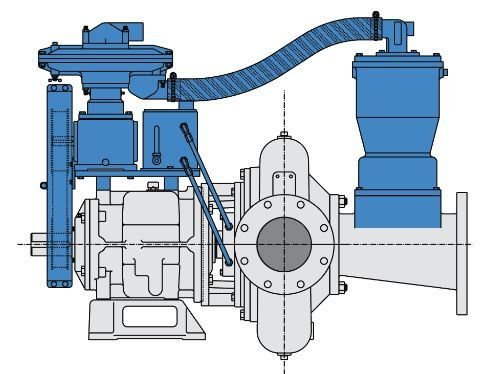

HYDRAULIC BALANCE LINE

Instead of boring large holes in the impeller to lower pressure in the stuffing box, Cornell employs a more effective solution; the external hydraulic balance line.

Reduces turbulence and improves hydraulic efficiency

Increases life of packing (or mechanical seal) and bearings

Provides positive control of axial forces

Reduces pump wear because abrasives aren’t trapped behind impeller/near shaft